Stainless Steel (SUS 304 or 316) Linen Chute (or Laundry Chute called by some) System is widely used in hotels and hospitals. We design, supply, fabricate and install CHUTEK SS linen chute for owners, operators, main contractors, mechanical trades, laundry specialists, etc.

Linen Chute System diminishes unnecessary vertical transport through cargo lift or even passenger lift for soiled linen.

Its application reduces labour use and the system is generally maintenance free.

|

|

|

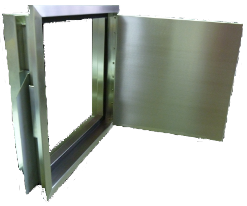

Stainless steel (SUS 304 or 316) linen intake / loading door in hairline (or No. 3) finish is self-closing, self-latching, side hinged and fire rated (up to 2 hours) carried with the PSB (Singapore) certificates and labels. Optionally, linen chute intake / loading doors are programmatically controlled by electrical interlocking system.

|

|

|

Linen chute trunk is usually made of 1.2mm to 3mm thickness stainless steel (SUS 304 or 316) plates in 2B finish. CHUTEK SS trunk has an expansion (telescopic) joint between floor support frames.

Linen Chute Door

Linen Chute Door

Door at Open Position

Door at Open Position

Trunk Installation in Progress

Trunk Installation in Progress

Intake Opening to Receive Door

Intake Opening to Receive Door